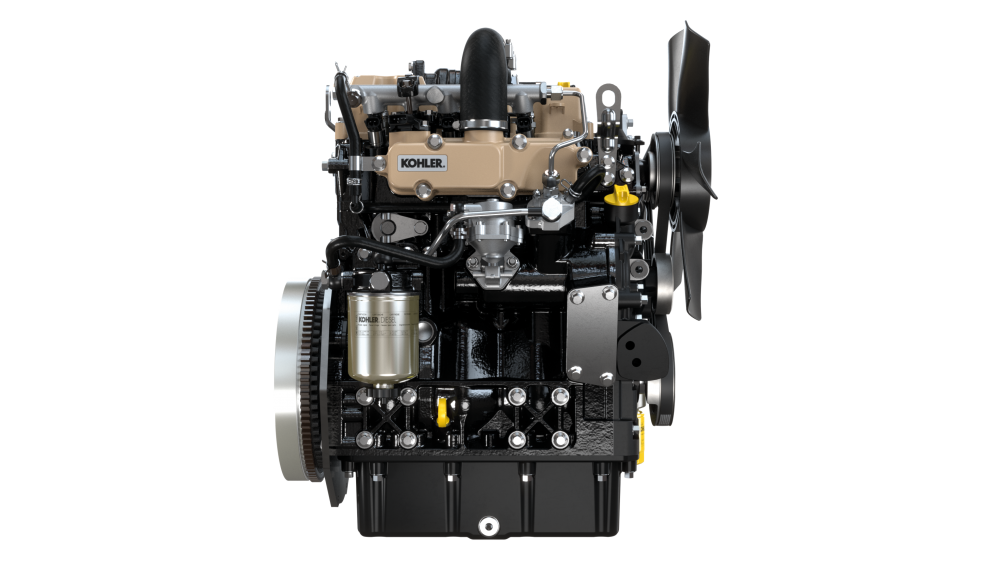

Kohler’s new KSD (Kohler Small Displacement) engines, unveiled globally Nov. 23, offer easy integration for applications needing 24.7-hp or less.

This new family of Kohler engines is suitable for all regions, complies with all standards worldwide, and is compatible with all kinds of machines.

Integrating an engine in any piece of equipment doesn’t mean just selecting and purchasing it. Kohler’s global team offers support throughout the process, during and after the engine installation, wherever customers are, whatever machine type they have.

Kohler offers the highest standards of support and solutions to transform complexity into simplicity. The KSD is the latest example of the company’s approach to the market and customers.

Kohler says KSD engines can be integrated easily with the more complex electronic systems of ever evolving machines.

KSD engines are versatile and can be integrated without modifying or redeveloping a machine.

They allow customized settings for any duty cycle and the ability to exchange data with few physical connections.

The product line currently has three models. Many others will join them in the next few years, Kohler says. Current models include KSD 1403NA (Naturally aspirated), KSD 1403TC (Turbocharged), KSD 1403TCA (Turbocharged and aftercooled).

The performance is outstanding. For example: High low-end torque: 95 Nm (70 ft.-lbs.) @ 1,000 rpm; Peak torque at low speed: 120 Nm (88.5 ft.-lbs.) @ 1,400 rpm; Peak power: 18.4 kW (24.7 hp) @ 1,800 rpm.

Low-emission compliance. A new engine below 19 kW (25.5 hp) that complies with all global emissions standards and fuels. And multi-fuel solutions will enrich the offering: diesel, gasoline, and propane.

KSD engines are controlled electronically, while being as simple to use as mechanical engines, said Kohler. The fuel system allows precise metering and excellent response, resulting in time savings and increased productivity. Durable components make the engine ready for heavy-duty applications.

Dual-side servicing and full flexibility of fan position fit a wide range of machines.

Integration between the engine and the machine offers better response, drive by wire, speed control, auto stop, pedal map setting, and fan speed control.

The electronic controls allow the engine to maintain high performance at high altitude.

Furthermore, these features allow you to optimize fuel consumption by controlling the hydraulics of the machine and the engine load and speed.

Prognostic, diagnostic, geolocation, remote monitoring, and a service interval of up to 500 hours, for both oil and fuel filters reduce maintenance and simplify servicing.