High dynamic response of the travel drive and implement hydraulics, on mobile equipment even at reduced diesel engine speeds, and for Tier 4 final engines, is the goal Rexroth has achieved with their Diesel Hydraulic Control(DHC). Developed together with the diesel engine specialists from Bosch, this electronic Bodas system solution for engine management and drive and working hydraulics reduces diesel fuel consumption by up to 20 percent. The Tier 4 emissions regulations for mobile work equipment, due to take effect in 2014, will likely result in significantly poorer load response of diesel engines. Furthermore, manufacturers of excavators, telehandlers, and other mobile equipment are reducing engine speeds to conserve diesel fuel. The control devices used until now for the drive and working hydraulics cannot compensate for this sluggishness. The potential risk is lower productivity.

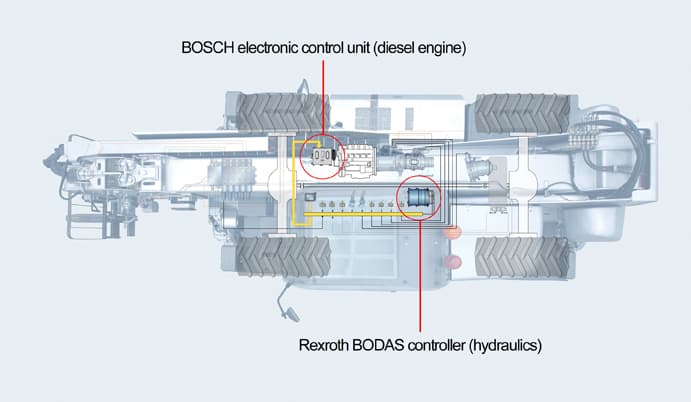

With DHC, Rexroth has teamed with Bosch to develop a new control strategy which retains the accustomed lively response of the travel drive and implement hydraulics even under conditions of diminished load response and lower engine speeds. DHC changes the traditional function sequence and lets the diesel engine know of expected load requirements. This is accomplished using matched controllers from Bosch for engine management and from Rexroth for the travel drive and implement hydraulics, using a common special map. This DHC system map represents the vehicle-specific relationships between rpms, efficiency, and torque.

Diesel Hydraulic Control continuously determines the demands of the travel drive and implements hydraulics, and uses this information to dynamically calculate the optimal operating points for the diesel engine and hydraulic components by means of the DHC system map. In practice, the joystick for the implement hydraulics, for example, transmits pending work requirements directly to the DHC, which in turn passes this requirement to the diesel ECU. This allows the engine time to prepare for the imminent mechanical load.

The world’s first combined controller solution compensates in this way for the expected poorer load response of Tier 4 final diesel engines. At the same time DHC makes it possible to operate the equipment at the accustomed dynamic response levels in spite of lower engine speeds, thereby saving fuel.

Since DHC means that the diesel engine only provides as much power as the machine actually needs at any given moment, diesel fuel consumption is reduced compared with current figures. Fuel savings of up to 20 percent as measured in real-life testing will reduce the total cost of ownership for operators with no sacrifice in dynamic response of the travel drive and implement hydraulics.