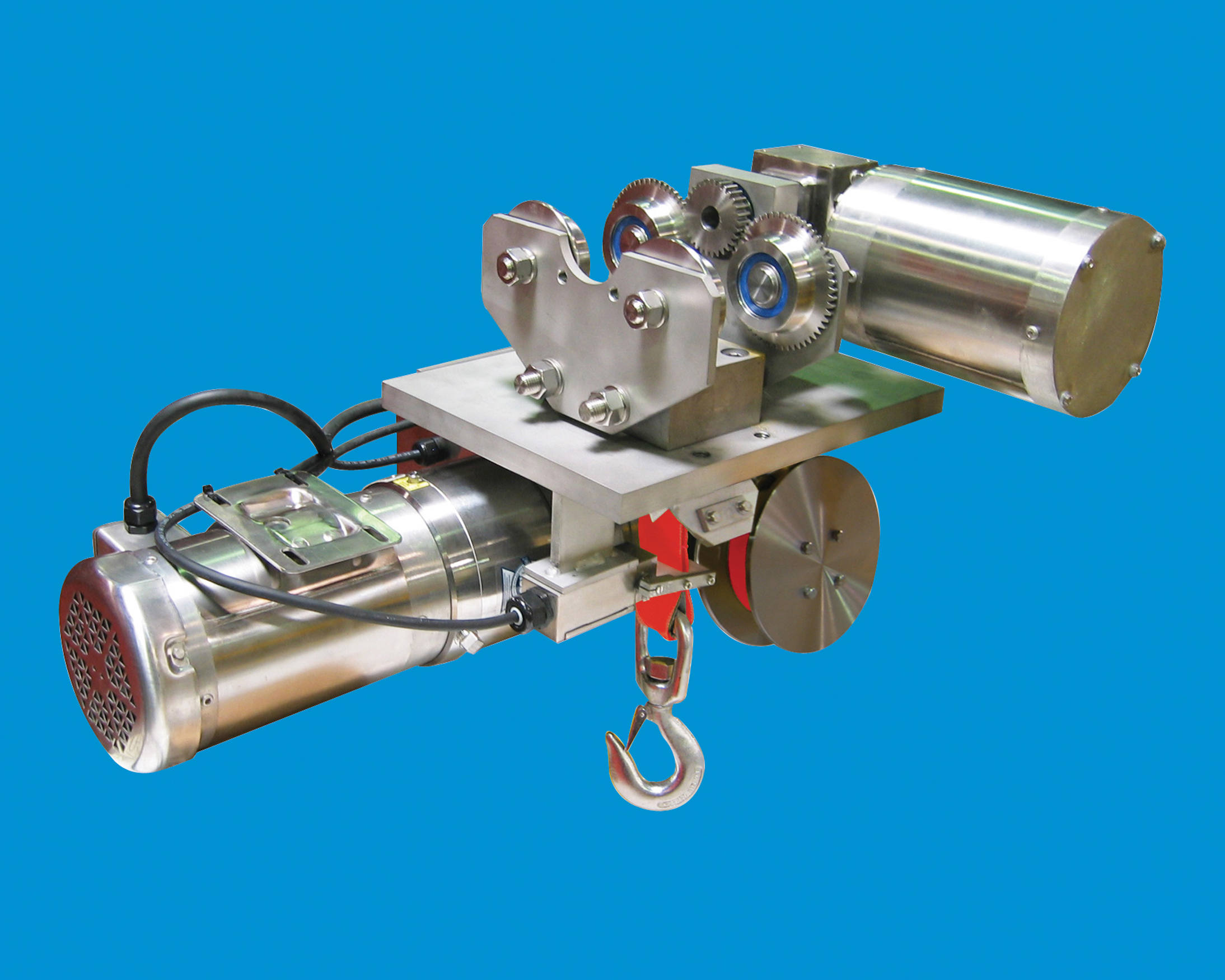

The David Round Co., Inc., Streetsboro, Ohio, has announced the availability of clean room strap hoist products featuring urethane coated lifting straps for easy cleaning. The hoists are designed for pharmaceutical manufacturing environments, food processors, microelectronics manufacturers, or wherever lifting in a clean room is required. A number of models and configurations with stainless steel trolleys are available to accommodate up to 4,000 pounds.

These all stainless steel clean room strap hoists feature lubrication-free urethane-coated lifting straps to eliminate the contamination potential associated with chain hoists or wire rope hoists. Because there is no metal-on-metal chain abrasion or wire rope wear, metallic dust and particulate contamination are avoided. The strap never needs lubrication, eliminating potential additional environmental contaminants. These hoists feature all polished stainless steel external components to withstand harsh cleaning chemicals. There are no painted surfaces, as paint (even FDA-approved epoxies) is not tolerated in many clean room environments. Smooth ground welds, flush mounting faces and plugged fasteners also help to reduce potential contamination.

All David Round stainless steel hoist products come standard with sealed gearing with food-grade lubrication, a clean room grade motor and motor brake, stainless steel load hook with latch, and stainless steel NEMA 4X enclosure. Many options, as well as fully custom-engineered hoists, are available.