Elevated work inherently carries the risk of falling from that elevation and sustaining an injury as a result of the fall. Many workers must utilize mobile elevated work platforms (MEWPS) to access elevated areas because they are recognized as a conventionally safer alternative to portable ladders. However, they still pose many risks to workers from falling or being accidentally ejected from the equipment.

There are various solutions for providing fall protection for non-articulating lifts (also referred to as Group A or scissor lifts) and articulating lifts (also referred to as Group B or boom lifts) that can help maintain regulatory compliance and protect workers.

Scissor Lifts

Most people consider the guardrails on scissor lifts as adequate fall protection, and they would be correct if achieving minimum OSHA requirements were the goal. However, exceeding minimum requirements is the only way to build fully comprehensive fall protection programs that plan for the unexpected and protect workers.

Additionally, there is an ongoing debate among industry professionals about whether more robust fall protection is required while working on scissor lifts. Many scissor lifts are now manufactured with an engineered anchor point on one (or more) of the midrails. OSHA is clear that equipment operators must follow the manufacturer’s instructions. If the manufacturer instructs operators to use the anchorage when using the scissor lift, but OSHA does not explicitly require fall protection on scissor lifts, many employers are left uncertain about how to proceed.

It is also important to note that the guardrails on scissor lifts should never be used as a tie-off point. Guardrails are only rated to withstand up to 200 pounds of force while falls can generate 1,800 pounds of force or more, depending on the nature of the fall.

In any case, travel restraint equipment is regarded as the preferred form of fall protection for scissor lifts. Adjustable length lanyards are a popular option for travel restraint as they allow workers to easily walk about their platform while adjusting the length of their lanyard to prevent them from leaving the platform.

If a worker is prevented from leaving the platform, they virtually eliminate the chance of falling out of the scissor lift. Of course, this system depends on the operator using the restraint equipment properly. Proper training can help increase awareness and empower workers to be active in providing personal safety while working at heights.

Boom Lifts

Fall protection requirements are clearer for boom lifts, as OSHA clearly requires boom lift operators to use either travel restraint or fall arrest equipment. However, the Army Corps of Engineers’ EM385 standard, which has jurisdiction over many federal government properties and DoD projects, only permits the use of travel restraint methods in boom lifts. In theory, travel restraint equipment prevents falls from occurring, while fall arrest equipment can only mitigate the severity of fall injuries.

SRLs vs. Shock-Absorbing Lanyards

If employers want to provide MEWP operators with fall arrest equipment to proactively protect them from falls, they must ensure that the correct fall arrest equipment is utilized. Historically, six-foot shock-absorbing lanyards were the only option available for fall arrest. Lanyard users must fall the length of the lanyard before it can begin decelerating the fall, absorbing fall forces and successfully arrest the fall. This distance is referred to as the minimum required fall clearance and can be confirmed either on the product’s label or in the manufacturer’s instructions.

For most six-foot shock-absorbing lanyards, however, the minimum fall clearance required is 18.5 feet. Operators relying on a lanyard beneath that height are subject to encounter the ground before their fall is arrested, which means they will experience greater fall forces and will likely suffer more severe injury.

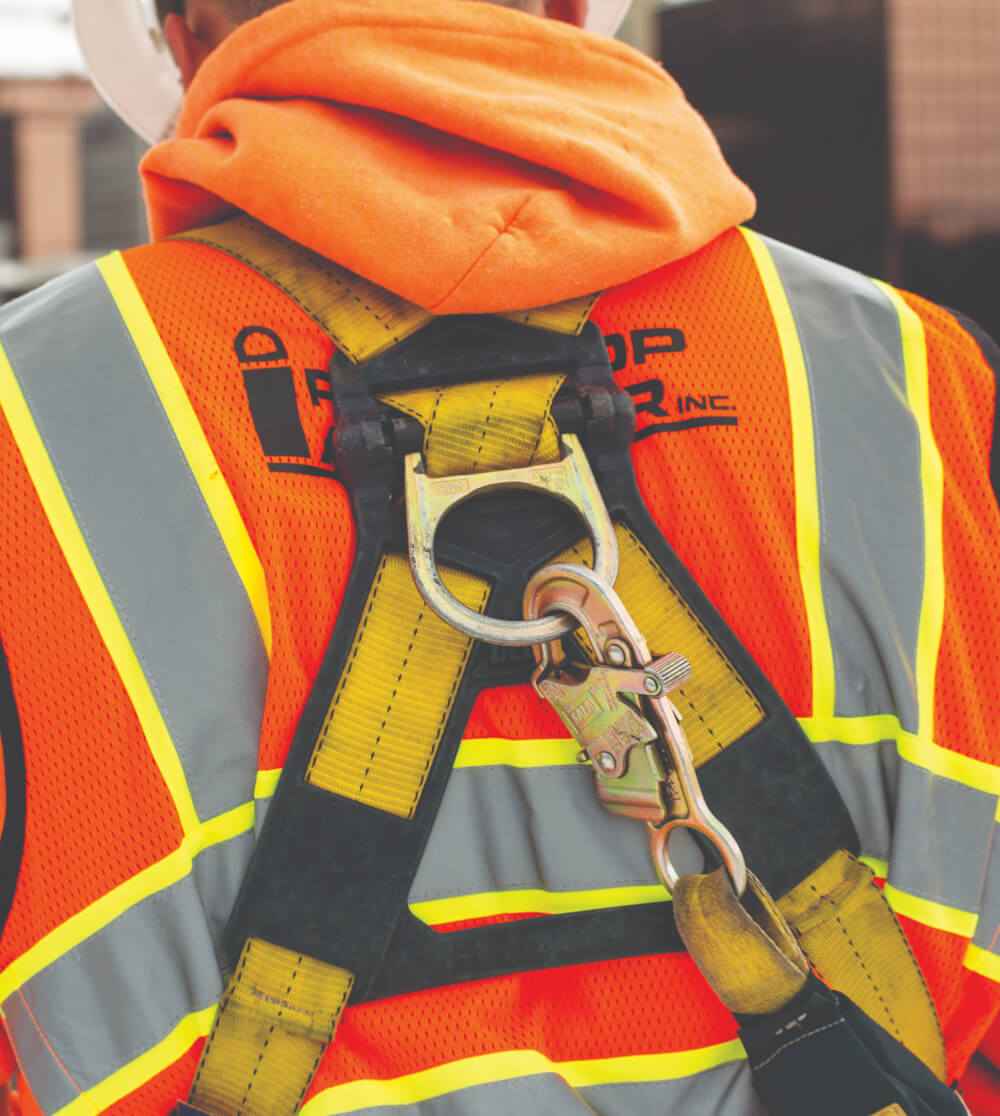

SRLs (Self-Retracting Lifelines) on the other hand, activate almost immediately after a fall occurs. However, since anchor points are commonly located below the level of a user’s dorsal d-ring on their fall protection harness, a Class 2 SRL will be required, per the ANSI Z359.14-2021 update that took effect in August 2023.

SRLs have soared in popularity in recent years because they help decrease the amount of force generated during a fall and require less fall clearance. In the case of boom lifts, increased fall forces could lead to potential tip-overs, significantly increasing the likelihood of severe injury.

Meeting Obligations

According to the International Powered Access Federation (IPAF), the two leading MEWP categories involved in fall incidents are scissor lifts and boom lifts, accounting for 26% and 24% of all reported falls, respectively. From 2012 to 2022, approximately 55% of falls reported to IPAF resulted in a worker fatality.

Employers have an obligation to provide effective safety equipment and train workers on the importance of properly using fall protection equipment when employees are exposed to fall hazards. With the right resources and modern technology, workers can be protected from falls, and tragedies can be prevented.