You can’t miss the equipment on a utility construction site, aerials, digger derricks, and boom trucks dominate the landscape. But behind the scenes, it’s the rigging gear that often makes the difference between a safe lift and a dangerous one. Properly chosen rigging products are the backbone of dependable, efficient lifting that powers the utility industry.

“Lifting capacity is always a key factor, but rigging decisions in utility construction involve much more,” says Felix Nyberg, VP of product – portfolio optimization at Kito Crosby. “You have to factor in site conditions, equipment combinations, and the durability of gear that’s often pushed to its limits. And durability and flexibility go hand in hand on utility jobsites.”

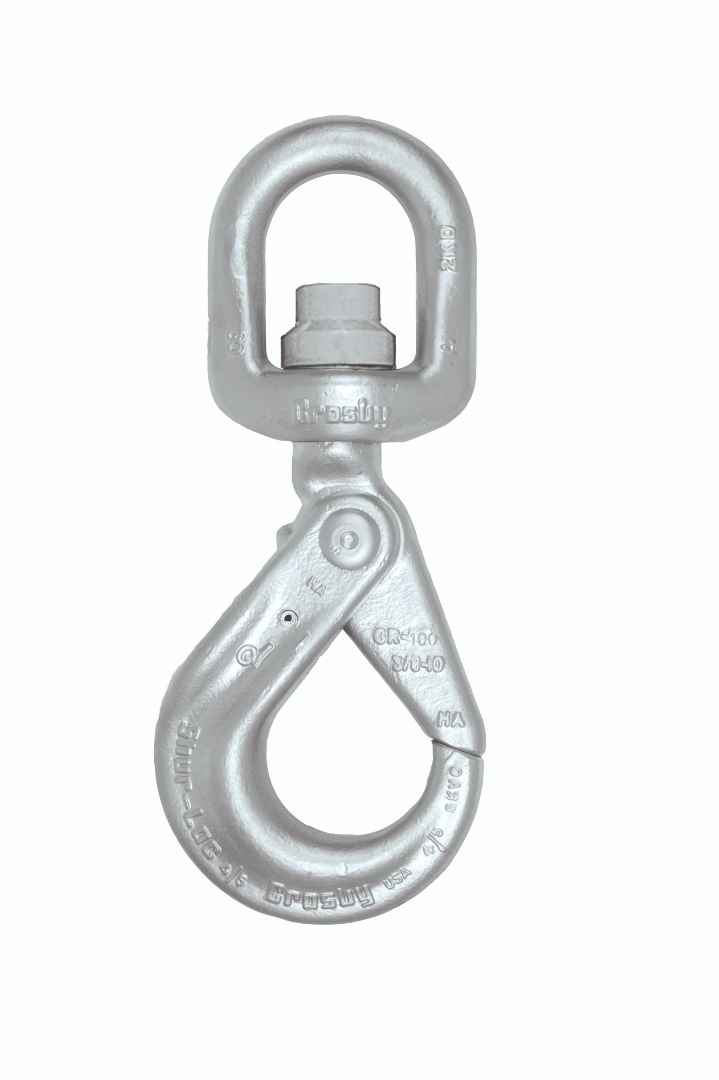

Crosby Shur-loc locking hooks mechanically lock in place for the duration of the lift and prevent opening until the load is relaxed and the safety trigger is engaged. The bearing swivel version allows this hook to swivel under load as well.

Above-ground utility work demands rigging that can adapt to different equipment setups, while underground jobs often involving digger derricks and excavators require gear that can withstand high abuse and constant movement, Nyberg added.

Right Tools

Andy Baranowski, product manager at Kito Crosby, said the best place to start is by understanding the range of rigging products available and knowing which one fits the application. In the company’s product line are a wide range of choices, including:

Smart Rigging

Technology also plays a growing role in utility and construction jobsite efficiency and safety. A technology-centric focus, Baranowski noted can be realized with mechanical and electronic innovations that are continuing to advance the industry.

Take the Crosby|SP COLT tension meter, for instance. This clamp-on device provides real-time tension readings in wire rope, which are critical for verifying proper tension during overhead line installations.

For pulling, tensioning, or lifting heavy loads, there is the Kito LB-SL lever hoist. Rated to over 19,800 pounds, it features fine-tooth gears for minimal effort, a load pressure brake, and a backup safety lock that engages automatically in the event of failure. “The LB-SL is built for safe overhead use and gives operators fine control without compromising on muscle,” Baranowski said.

For overhead power line construction, the Kito LB-SL lever hoist can be used when pulling, tensioning and lifting loads. The lever hoist has a load capacity over 19,800 pounds.

Other products available from Kito Crosby include the manufacturer’s GrabiQ chain sling system, developed by Gunnebo Industries. It allows operators to lift asymmetrical loads using a single adjustable sling, rather than juggling long and short ones. It also supports low headroom lifts and adapts easily to loads like bars, tubes, and pipes.

The Midgrab Chain Shortener (MIG) is also available for adding flexibility. By letting operators shorten chain legs at the hook, closer to the load, it keeps adjustments simple and prevents disengagement during use.

The Midgrab Chain Shortener (MIG) lets riggers shorten chain legs at the hook, closer to the load and prevents disengagement during use.

Training Is Key

While the right equipment is crucial, Felix Nyberg is quick to point out that knowledge matters just as much. Essential to the job at-hand is the training behind the equipment.

“Online selection tools can also help guide customers toward the right rigging solutions, but training ensures they’re used correctly,” Nyberg said. “That’s where jobsite safety and efficiency really begin.”

Proper rigging not only minimizes risk,” Nyberg added. “It enhances crew productivity and can lead to significant cost savings. In the end “it’s often the smallest decisions that have the biggest safety impact.”

Why Self-Locking Hooks Matter

First introduced by Gunnebo Industries in the 1960s, self-locking hooks were developed in response to a common and dangerous problem: crews relying on open hooks or spring-latch hooks that would wear out or fail on the job. A failed latch doesn’t just violate OSHA and ASME B30.9 standards—it puts workers at serious risk.

Self-locking hooks eliminate manual connections and reduce pinch-point exposure. Once loaded, they automatically close and stay locked until the load is fully released. This simple innovation adds a crucial layer of safety, making every lift more secure.