In summer conditions, workers are exposed to intense solar radiation, elevated surface temperatures on materials like steel decking and high ambient humidity that increases the risk of heat-related stress. And while some trades pull back, lift operations keep moving. Timelines stay tight, equipment keeps cycling and precision work at height doesn’t stop just because the temperature is rising.

But there’s a silent threat threading through every shift: heat stress. And it doesn’t just affect comfort but erodes safety one symptom at a time.

Heat Doesn’t Ask Permission

Operating a lift in the summer isn’t just another shift; it can be a grind against biology. Whether you’re in an aerial work platform, working from a hoist basket or staging lifts on hot concrete, you’re battling glare, sweat and often minimal airflow.

That heat builds up fast. Gloves get slick, grip strength fades and vision can go hazy. And all it takes is one misstep or shaky movement 20 feet in the air for a routine task to turn risky.

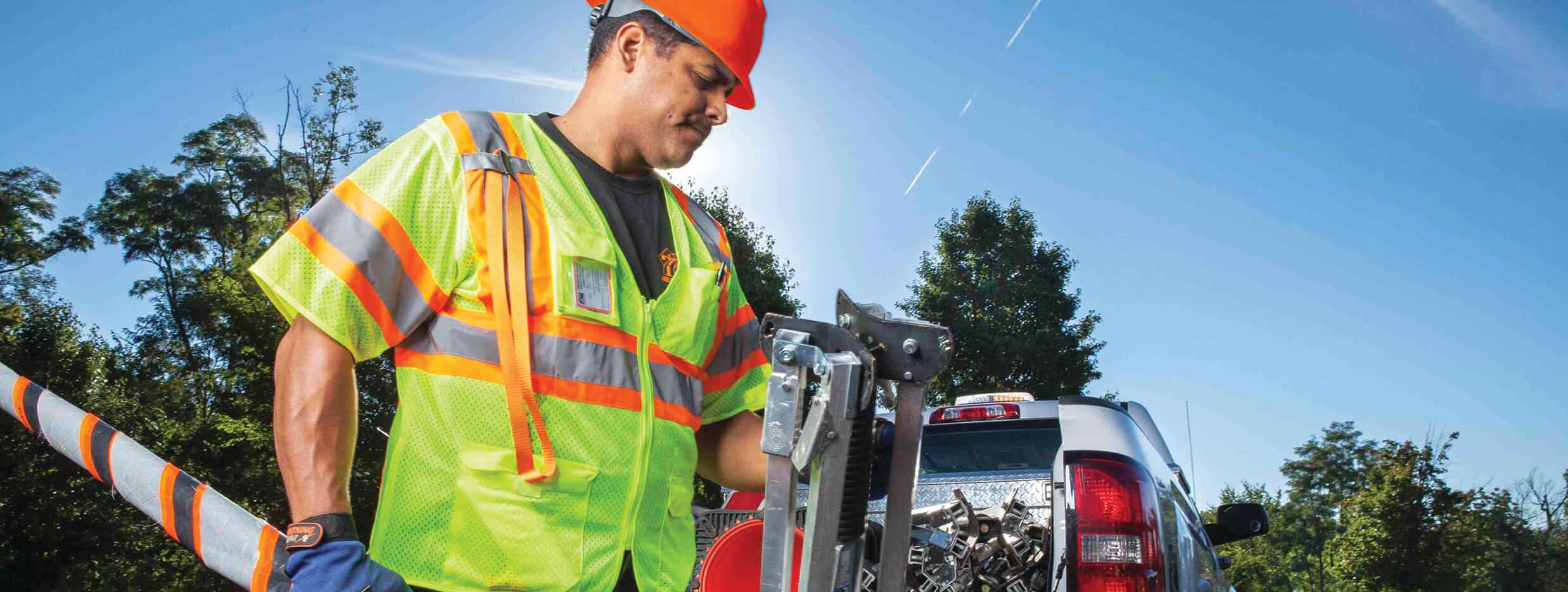

Down below as well, spotters can be standing on black top that radiates heat like a skillet. Some days, there’s nowhere to hide, and the symptoms of heat stress — dizziness, fatigue, blurry concentration — don’t show up like a red warning light, but creep in quietly and quickly.

The Time To Stop Is Now

It’s not about being “tough.” It’s about being smart. If someone on your crew looks glassy-eyed, is moving slowly or is unsteady on their feet — don’t wait. Pause the lift. Step in. It’s smarter for your schedule to take a 10-minute breather instead of experiencing a dropped load or a collapsed operator.

Set the expectation from day one: safety always overrides the stopwatch. Shade and water stations are just the table stakes. A real heat protocol goes much deeper:

Don’t forget that machines feel the heat too. Heat messes with hydraulics while sensors can get flaky. Steel expands, and electronics drift. If you’re pushing heavy equipment in high-stress conditions, double down on pre-use inspections.

Check everything: fluid levels, hoses, electronics, brakes, boom function. Then check it again. Tighten the reporting loop so even the smallest hiccup — odd noise, sluggish response, hairline crack — gets flagged quickly. And if something feels even a little off, shut it down and speak up immediately.

New Hires Aren’t Always Heat-Ready

Keep in mind that a new operator from Minnesota might not recognize how hard Florida sun can hit by 10 a.m. That’s why smart crews use heat acclimatization protocols:

And diet matters more than people think: too much caffeine amps up dehydration, and salty snacks can throw off fluid balance. Energy drinks might give you a short-term jolt, but that boost can come at a cost. Talk to your team about good food choices that make sharp minds, steady hands and lasting energy possible.

Lead Like It Matters

You can spot a site’s safety culture immediately. If a foreman is drinking plenty of water, pushing breaks and proactively checking on the crew, that’s the kind of behavior that spreads. But if the lead shrugs off heat safety, don’t be surprised when others do too.

Lifting and hoisting demands laser focus and confidence on the controls, and heat stress can chip away at your ability to perform under pressure. Don’t leave your safety strategy to the next heat wave. Build it and own it now with training and education, technology that fits your worksites and protocols designed for jobs that run hot, high and heavy.