By Steve Kiskunas, product manager for telescopic material handlers, Manitou

All equipment trends start with a slow rumble and eventually build into a wave taking over whole industries.

Many of us are all old enough to remember when those quaint little skid steers with tracks came out — now compact track loaders exponentially surpass skid steers in annual sales.

Commercial snow removal operations have shifted heavily to traditional construction equipment over trucks with plows compared to twenty years ago.

Also, it wasn’t that long ago that people thought machine control was a niche product.

I genuinely believe there will be a similar shift in North American building construction techniques and practices as more fleet managers, contractors and rental businesses become familiar with the awesome capabilities of rotating telehandlers.

Greater rotating telehandler adoption will be driven by a number of industry trends and shifts in how job sites work.

So, what do you need to know about rotating telehandlers, and how do they compare to other types of construction equipment used today to perform material handling and other lift-and-place functions? Read on to find out.

How Much Reach and Height?

When asking the question of “why would you want a rotating telehandler over a traditional telehandler?”, The answer largely comes down to height, reach, and lifting capacity. Our largest construction telehandler, the Manitou MTA 12055, offers a maximum lifting capacity of 12,000 lbs. and a maximum lifting height of just over 55' — as well as a maximum forward reach of 40' 9".

By way of comparison, the largest Manitou rotating telehandler features lifting heights and maximum outreach (113' 10" and 91' 10") more than twice that of the largest traditional telehandler, as well as a higher maximum capacity of 15,432 lbs.

Obviously, lifting charts and best practices are required for safety, but it’s clear that if you need more lifting height and reach, but don’t need a full crane, a rotating telehandler can be a worthy addition to your fleet.

How Much Area to Position the Machine/The Benefits of a Static Machine

Job sites — even the big ones — are more cramped for space than ever before. On top of that, the consistent movement of equipment creates “opportunities for exposure” for that equipment to hit other equipment, infrastructure on the site, or other workers.

Traditional telehandlers, skid steers, and other equipment built for transferring palletized goods around sites all require the machine to be mobile to move their materials from position to position. The same goes for scissor lifts and other working platforms.

There’s also a continued/increased movement to minimize traffic on job sites.

This could be for reasons as simple as not tracking mud onto the road in a residential neighborhood, a desire to minimize site rework, or to avoid disturbing underground utilities on job sites where that site infrastructure already exists.

A great benefit of rotating telehandlers is that, for many job sites, the machine can be anchored in a single spot and simply rotated to reach, lift, and place materials throughout the site — never having to move.

Thanks to a wide range of attachments and systems capable of working with the machines (see the three-in-one commentary that follows), these machines can help reduce and eliminate significant heavy traffic on the job site.

The Power of Remote Control

Speaking of industry trends, remote operation is a massive industry buzz technology right now.

While there are applications where remote operation can help keep operators out of hazardous environments, there are extremely practical (if a little more mundane) tasks being performed via remote control every day — and that’s the remote operation of a rotating telehandler while the operator stands closer to where the work is happening.

Select rotating telehandlers feature remote control capabilities that put the machine operator elsewhere on the site (versus in the cab), giving them greater perspective and visibility of the job site.

Contractors who have figured out how to make this work with the flow of their job site have been very pleased.

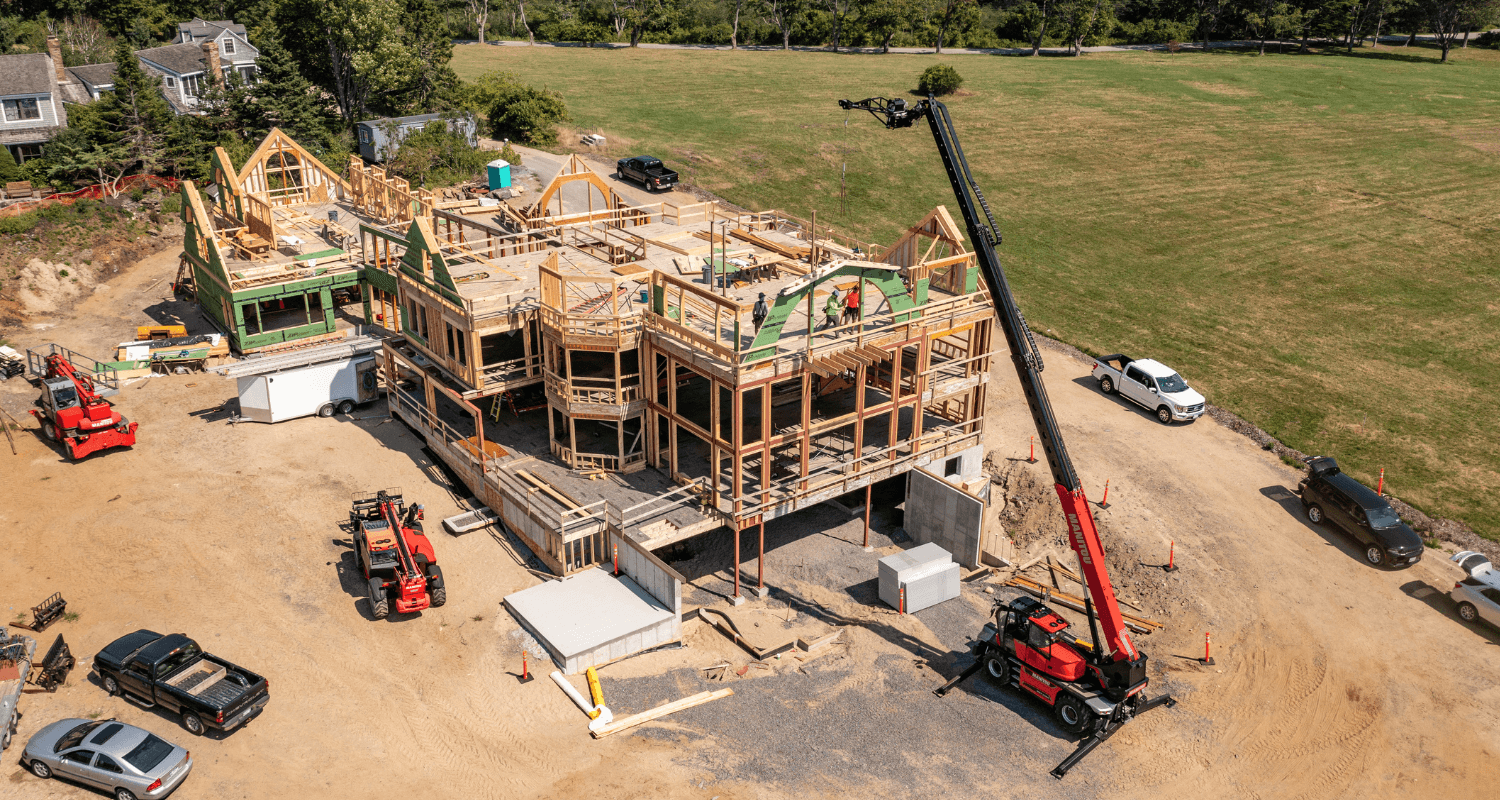

An example: a large home builder may use the forks attachment to unload a pallet of material and place it on the third story of the build

The operator is there standing next to the truck to make sure the pallet is grabbed securely, and then they walk up to the third story landing spot to make sure the pallet gets placed right where they want it.

This allows for greater accuracy in work and greater awareness of the job site compared to what the operator could experience in the cab.

200 Degrees or Full 360-Degree Rotation?

It’s important to note as you begin your rotating telehandler journey: not all models rotate 360 degrees. Some entry level models only rotate 200 degrees in either direction versus offering the continuous rotation of a 360-degree model.

This can be great for contractors just looking to get that added height and reach, or the three-in-one capabilities, but who don’t need the unlimited rotational ability.

The Best of Both Worlds

Electrification is also still at the forefront of industry trends, and rotating telehandlers on the market today help contractors achieve this in two ways.

Of course, if you want, a traditional all-diesel machine is available. Manitou manufacturers both all-electric versions of select models, as well as a “hybrid” model of each that includes an onboard diesel engine “range extender” that ensures the machine is operational under diesel power even if away from a charging station.

That range extender then also recharges the battery as it operates, giving the operator the best of both worlds.

Three-in-One Capabilities

Fleet management in 2024 is all about the intelligent utilization of the equipment you have and, when possible, consolidating fleet assets for optimal carrying costs and total cost of ownership.

Like the backhoe, or other multi-use machines, a rotating telehandler is actually three machines in one: a telescopic telehandler, a work platform, and a winch with a jib.

Having these capabilities in a single machine may alleviate the need to own numerous machines or, at the very least, have fewer machines on-site to minimize traffic and clutter.

Much like skid steers and CTLs, almost countless attachments are available for these machines, from work platforms and jibs to concrete mixing buckets and swing fork carriages.

For example, Manitou rotating telehandlers have an attachment recognition system within the machine that automatically sends the appropriate lifting charts and attachment information to the monitor to best inform the operator about the attachment’s operating characteristics.

Can a rotating telehandler replace the true performance of a construction crane? No – cranes have an advantage in being able to lift heavier loads.

But, depending on the type of work you do, it may help reduce the need for crane rentals. And it’s certainly more versatile in day-to-day work. Overall, it’s important to think of these machines as multipurpose work systems/platforms versus ‘just another machine.’ As the benefits of these machines become more evident, you can expect even greater acceptance of rotating telehandlers on job sites throughout North America.