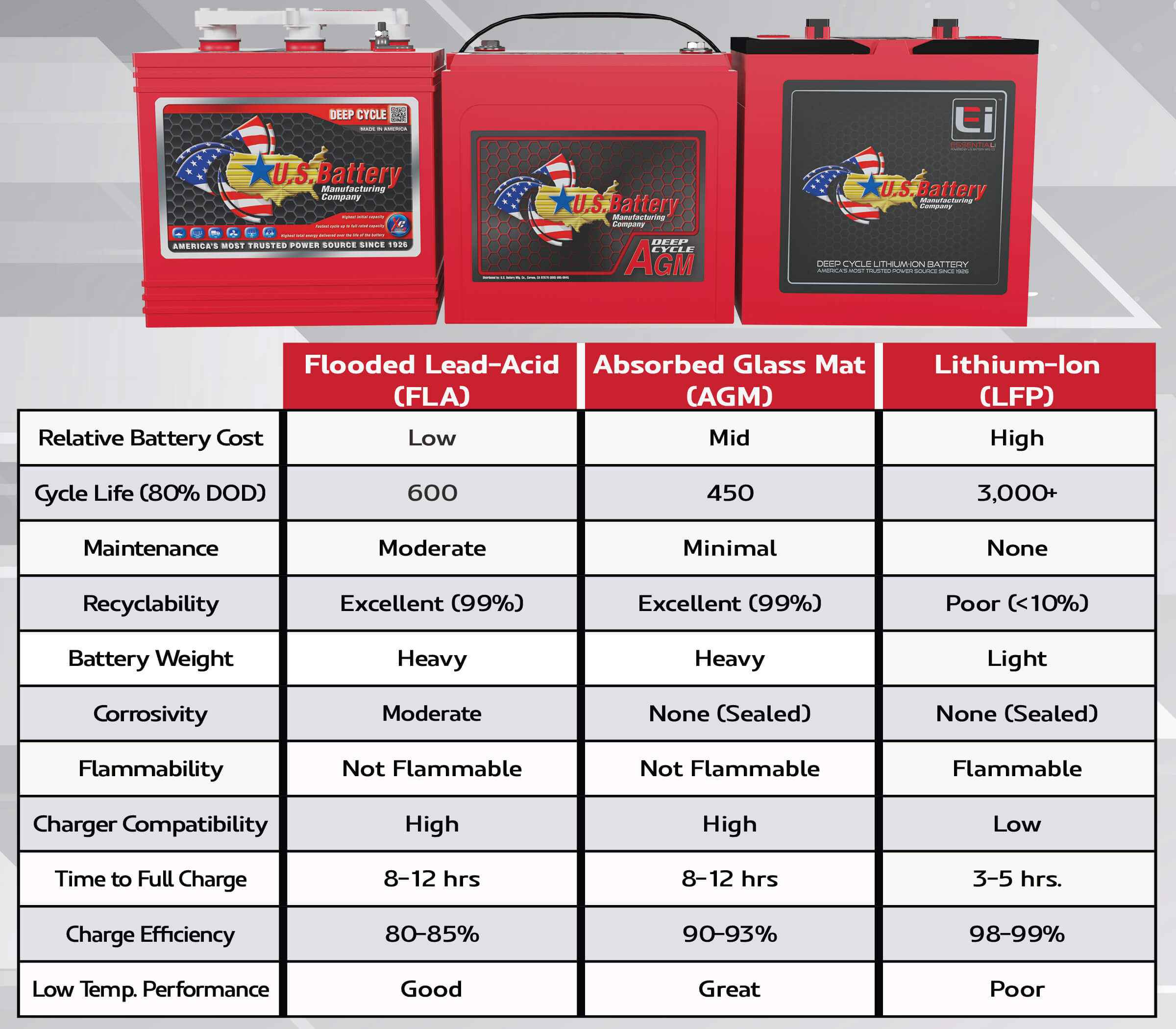

(Sponsored Content) — The latest compact lifting equipment requires deep-cycle batteries to power it. Although they can provide long operation times and reliable use, eventually the batteries will need replacing. The cost of replacing batteries is often the first consideration, but it's also crucial to understand that various battery types (technologies) can affect price in different ways. The various battery types can include factors such as maintenance, recyclability, operation time, charging time, and longevity, all of which can impact the long-term costs of operation.

Understanding the benefits of each battery type can help you select the best battery to meet your needs. There are three primary battery types for Battery-powered lifting equipment: Flooded Lead-Acid, Absorbed Glass Mat, and Lithium-Ion. All three offer distinct advantages and disadvantages depending on your use.

Flooded Lead-Acid (FLA)

Flooded lead-acid batteries continue to be a reliable and cost-effective option. Improvements to this over 150-year-old technology include increased initial capacity, faster cycle-up to peak capacity, and improved cycle life.

FLA batteries have the electrodes submerged in an aqueous electrolyte. During use, water in the electrolyte is lost from electrolysis and must be replaced. This loss requires regular water replacement, in addition to the cleaning and re-tightening of the terminals. Before operation, the batteries must be fully charged to prevent sulfation and to avoid freezing in cold weather. FLA batteries are safe, reliable, low-cost, and offer a wide range of capacities. They are also essentially 100% recyclable – the highest in the industry.

Advantages:

Most cost-effective

Nearly 100% recyclable

Long cycle life

Extremely reliable and used in many industries worldwide

Heavy (compared to Li batteries of the same voltage and amp-hour rating, but is often used as a counterweight/balance on some equipment

Disadvantages:

Should not be discharged beyond 50% of its charge (Depth of Discharge)

Requires monthly maintenance

Requires ventilation

Absorbed Glass Mat (AGM)

AGM batteries have the electrolyte absorbed in special glass mat separators that surround the battery's electrodes and immobilize it. This design allows the battery to be sealed with a special one-way valve to control gassing and water loss. Thus, eliminating the need to add water for near maintenance-free operation. The cell design also prevents electrolyte leakage in even the most extreme conditions.

AGM batteries are more expensive than FLA batteries, but they are an excellent option in applications in which the batteries are difficult to access for regular maintenance. AGM design advancements in positive electrode corrosion resistance and carbon-enhanced negative active materials have improved their charge acceptance in a partial state of charge applications and have increased cycle life over previous models. AGM batteries are also nearly 100% recyclable.

Advantages:

Zero maintenance

Nearly 100 % recyclable

Spill-proof and shock-resistant

Withstands colder temperatures compared to FLA batteries

Better in tight battery compartments with less ventilation

Low self-discharge rate

Heavy (compared to Li batteries of the same voltage and amp-hour rating, but often used as a counterweight/balance on some equipment

Disadvantages:

Higher in initial cost than FLA batteries of the same voltage and amp-hour rating

Shorter Cycle Life than FLA batteries

Lithium-ion (LFP)

Lithium-ion batteries deliver peak power consistently and over extended periods, so the power doesn't degrade as the charge begins to run out. These batteries have a battery management system (BMS) built into them, needed to regulate temperatures during charging and discharging. Some have special cell packaging for cooling, while others also have built-in heaters for use in extreme cold temperatures.

Deep-cycle Li batteries typically demonstrate increased average cycle-life over FLA and AGM batteries (from 2,000 to 5,000 cycles) and, unlike other chemistries, they can be discharged beyond 50-percent Depth of Discharge (DOD) without reducing cycle life. Lithium batteries also do not require special maintenance and are lighter than FLA or AGM batteries in comparable applications. Lithium batteries also come at a higher initial cost than FLA and AGM chemistries. Currently, only a small percentage of lithium-ion batteries are recycled, necessitating special and costly disposal methods.

Advantages:

Zero maintenance

Charge and discharge performance optimized by internal BMS

Longer cycle life

Low self-discharge rate

UL Certification and IP65-approved cases on 24V or 48V models

Reduced weight compared to FLA and AGM batteries of similar voltage and amp-hour ratings

Disadvantages:

Higher upfront cost than FLA or AGM batteries

Very low rate of recyclability

Some Li cells are better than others (check with the manufacturer)

Reduced weight may not work well as a counterweight (balance) for some equipment

Battery manufacturers such as U.S. Battery have a complete information library on their website, showcasing various battery chemistries and models specifically for AWP, crane, forklift, walkie stackers, and other applications. There, you can compare cycle-life ratings, obtain instruction manuals, determine energy storage capacity, and ultimately decide what's best for your system and energy needs. Visit usbattery.com.