Even with a soggy start, the 2025 Utility Expo, held Oct. 5-7 at the Kentucky Exposition Center in Louisville, Kentucky, featured more than 1,000 exhibitors who powered through the rain and showcased the latest in equipment, technology and tools for the utility and construction industries. These products underscored the industry’s continued push for smarter, safer and more efficient equipment.

Digging Deeper

With an impressive outdoor exhibit, Ditch Witch showcased a new range of underground construction equipment and digital tools. Its Orange Intel telematics system provides real-time machine health, fuel usage, location and drilling data, helping operators monitor equipment and reduce downtime.

The JT21 horizontal directional drill delivers 21,000 pounds of pullback, 20,000 pounds of thrust and 2,250 foot-pounds of torque, with 40% more downhole horsepower and 53% faster carriage speed than its predecessor. The W8 hydrovac offers the power of larger models in a compact footprint, featuring an 8-inch dig tube, 800-gallon water tank and 8-cubic-yard spoils capacity for urban and residential work. The SK1000 stand-on skid steer pairs a 23.7-horsepower Yanmar turbo engine with a 1,000-pound operating capacity.

Subsite’s UtiliView app also debuted, linking Esri mapping software with the UtiliGuard 2 RTK locator for survey-grade utility mapping and instant data transfer.

Reach Higher with New Buckets

PALFINGER unveiled two new bucket truck models, the PB 41 AT and PB 30 T, built and assembled in Oklahoma City. The PB 41 AT features a minimum 700-pound lifting capacity from any position, a 46-foot working height, single-hand proportional upper controls, hydraulic platform leveling, a 90-degree bucket rotator, adjustable boom wear pads, replaceable pin bushings and powder-coated components.

The PB 30 T provides a 35-foot working height, 350-pound platform capacity and 390-degree non-continuous rotation. It includes a low 1-foot-4-inch bucket entry, speed-adjustable upper controls with start/stop functionality and rapid boom movements for faster positioning.

In addition to the new models, the company showcased the PB 38 AT P cable placer for fiber installation, the ETC MH 40 IH bucket truck for demanding insulated applications, the PAL Pro 43 mechanics truck with PSC 8029 service crane featuring real-time load moment indication and the PK 53002 SH knuckleboom crane for precise lifting and complex tasks.

Winch Work Simplified

Arrowhead Winch rolled out the BRADEN UCB12 utility winch bumper system, a front-mounted setup that integrates winch and capstan functions for multiple utility tasks. The UCB12 combines a 12,000-pound TR Series planetary hydraulic winch with a built-in capstan, enabling crews to pull lines, hoist equipment, set poles and handle underground cable tasks with less strain and more efficiency.

Its three-position manual clutch lets operators control the drum and capstan independently. The system features a heavy-duty steel bumper with a removable shell for easy maintenance, and optional bolt-on chassis installation simplifies fleet integration. Accessories such as cone racks, tow hooks, tie-downs and custom finishes expand versatility. Designed for cable pulling, hoisting, recovery, guy wire tensioning and vegetation management, the UCB12 combines multiple functions into one platform. The clutch handle sits within easy reach while the mechanism is protected inside the bumper, emphasizing usability and durability.

“The UCB12 is more than a winch — it’s a productivity tool designed for the real-world demands of utility crews,” said Paul Hiltenbeitel, director of sales at Arrowhead Winch. “By combining pulling, hoisting and recovery functions in one rugged system, it not only makes crews more efficient but also extends the value of every truck in the fleet.”

Compressed Innovation

A suite of new products from VMAC offers greater efficiency, versatility and ease of use for mobile utility and construction applications. The company revealed updates across gas-powered, electric and multifunction air systems designed to meet the demands of utility, construction and service fleets.

“At VMAC, we’ve really focused on simplicity, practicality and usability from the customer’s point of view, along with designing systems that are easier to build, service and repair in the field,” said Jamie McPherson, director of engineering at VMAC, during the company’s press event.

The G90 with FlexDrive AMS delivers up to 90 cubic feet per minute (CFM) at 100 pounds per square inch (psi) continuously and up to 50 CFM at 170 psi for high-pressure applications, automatically adjusting airflow based on load. Its rotary screw design supports continuous operation even in temperatures up to 100 degrees, while an intelligent microprocessor and optional telematics allow for remote monitoring and diagnostics.

VMAC also introduced the battery-electric E30 with Stealth Power, a compact, lightweight 30 CFM compressor powered by a 10-kilowatt nickel manganese cobalt battery pack, offering a 45-minute runtime, low noise levels and integrated telematics. The new 6-in-1 multifunction system, powered by Honda, combines air, hydraulics, welding, generator power, battery charging and boosting in one unit with quieter operation and fuel-saving standby modes.

“Our customers care that their systems are light, compact and run a long time — and that’s exactly what we delivered with VMAC,” said Christina Arrington, chief product officer at Stealth Power. “The E30 combines high energy density, intelligence and efficiency in a way that really benefits utility and service fleets.”

Additional innovations include the Multi-Port Air Manifold, which organizes pneumatic tools for service trucks and vans.

Excavators for Tight Spots

On display was Bobcat Company’s expanded compact excavator lineup, including the E17 and next-generation E20 models.

The E17 features a zero-tail-swing design, in-track swing frame and a retractable undercarriage that narrows from 53.5 inches to 38.6 inches for tight spaces. Its dozer blade folds to match the compact width, and it offers a rated lift capacity of 807 pounds. Operators benefit from low-effort joystick controls, a flat-floor cab with wider steps, LED lighting and standard pin-on attachments with optional couplers.

The updated E20 increases lift capacity to 1,098 pounds, with 24% more arm digging force and 26% more blade lift capacity than the previous model. It also features zero-tail-swing, a retractable undercarriage, a closed-center hydraulic system with a load-sensing pump and long-arm and blade configurations for improved reach and digging performance. Optional enclosed cab features include heat, Bluetooth radio, auto idle, auto shift and 3D grab handles.

Support That Holds Up

Presented for the first time, DICA’s EcoMax crane pad is a ground support solution that combines steel strength with recycled composite materials to improve durability and load distribution. The pad’s design links I-beam flanges with molded composite timbers to create a rigid structure, while a built-in center plate guides outrigger placement, reducing setup time and enhancing safety.

EcoMax offers two rating scenarios: a standard rating for full support and a “Bridge Rating” for use when ends are supported but the center spans a gap, enabling safe operation on uneven terrain. Additional features include lifting lugs for single or stacked handling and non-slip-coated steel components. The 24-square-foot pad is rated for 160,000 pounds, supporting cranes up to the 150-ton class.

Smarter Small Machines

Caterpillar updated its 5.5- to 11-ton mini hydraulic excavators and backhoe loaders to boost control, safety and productivity. The Cat 305 CR adds E-Fence to limit motion near structures and utilities, Indicate for real-time bucket feedback and a laser catcher option for precise grading.

The 308 CR and 309 CR feature the Cat C2.8 engine with maintenance-free emissions controls, a third auxiliary hydraulic circuit, a standard rearview camera and an optional side-view camera. The 308 CR also offers an angle blade with stick steer controls. The 303.5 CR software update improves transient speeds by 25% and productivity by 35%.

The Cat 440 and 450 backhoe loaders use the Cat C3.6 engine, raising the 440’s horsepower to 127 while maintaining 145 horsepower for the 450.

“With the new backhoes, you can tune the boom, stick, bucket and swing functions right from the touchscreen, and switch between seat- or pod-mounted joysticks, giving operators more control and flexibility on the job,” said David Young, product consultant for backhoe loaders at Caterpillar.

Optional LED lighting, product link telematics and switchable auxiliary flow enhance maintenance, monitoring and attachment versatility.

Elevating Efficiency

Elliott Equipment Company highlighted new equipment for transmission utility work, including an updated material-handling basket for E-Line aerials and the D86 Transmission Class digger derrick.

The self-leveling, rotating basket, available on the E145, E160 and E190 aerials, handles 1,500 pounds of material and 1,200 pounds of personnel, with a combined 2,000-pound rating. It rotates 165 degrees and includes an independently rotating material handler. The boom-mounted platform stays attached during travel and operation, reducing setup and meets ANSI A92.2 standards with grounding lugs, tool power circuits and wind ratings up to 30 miles per hour.

The D86 digger derrick covers the 80- to 90-foot transmission range, offering heavy-duty material handling, large-pad radial outriggers for stability and a tight turning radius for right-of-way work. A curbside operator console and utility-spec transmission body improve safety and efficiency, while Elliott’s hydraulic system powers the unit. The D86 expands the company’s digger derrick lineup, which now spans 47- to 115-foot models across distribution and transmission classes.

Anchors Made Easy

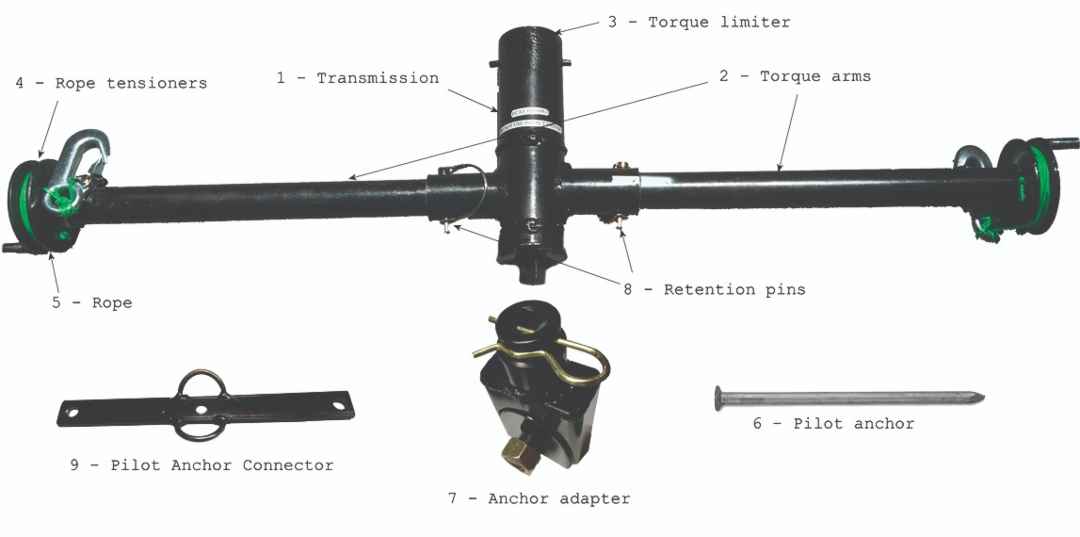

Making its debut at the Expo, 3S Craftings, LLC revealed its Force Couple Application Tool (FCAT), a portable earth anchor system that allows a single operator to set utility anchors.

The non-impacting, reversible tool counters bending forces during torque application, reducing operator fatigue and tool wear, and supports swappable gasoline or electric motors from multiple manufacturers. The FCAT accommodates a range of anchor sizes, including 1-inch guy wire anchors, while adapters minimize vibration, heat and stress at connection points.

Field tests reported installation times of four to five minutes per anchor, compared with 15 to 20 minutes by hand, with more than 1,000 anchors set without major failures.

“As you can tell, people just don’t want to do it by hand,” noted Steve Wojtaszek, business developer at 3S Craftings. “With our tool, a single operator can safely put in an anchor without the fatigue or wear you get using traditional impact methods.”

The FCAT lineup includes models that can deliver up to 2,000 foot-pounds of torque, providing an alternative to two-person augers and hydraulic units.

Quick Hits from the Floor

Stellar Industries showcased new and updated equipment aimed at boosting productivity for utility operations, including the 2025 TMAX 1-11 aluminum mechanic truck with expanded crane compatibility and improved shelving, the 2025 Hybrid Power Source with modular battery options and utility and telecom trailers designed for safer, more efficient field use.

Avient Corporation introduced its GridCore fiberglass composite utility poles, designed as a durable, corrosion-resistant alternative to wood, steel or concrete for electrical transmission and distribution. The poles feature customizable lengths, pre-drilled holes and optional accessories, and their lighter weight allows easier installation and reduced maintenance. Avient also highlighted its Glasforms line of pultruded rods, tubes and custom profiles, along with GlasArmor and ThermoBallistic panels, which provide ballistic-resistant protection for specialized applications.

As a new addition to its protective equipment lineup, Bullard unveiled the Type II + Safety Helmet. Designed to meet the ANSI/ISEA Z89.1 Type II standard, the helmet provides impact protection from both the top and sides while emphasizing a customizable fit. Its FlexBrim design allows quick, tool-free conversion between standard and full-brim configurations, and field-replaceable components extend its service life.

Condux International showcased new and updated tools for underground cable and fiber installation. The APS75 Hydraulic underground cable puller delivers 7,500 pounds of continuous pulling power with digital monitoring and data recording, while the Blue Ox cable puller provides 8,500 pounds and a hydraulically controlled boom for tight spaces. The Gulfstream 350+ fiber optic cable blower improves push force, motor efficiency and cold-weather performance. Copper Python Traceable Duct Rodders feature a copper core to help locate buried conduits.

Custom Truck One Source and Load King Manufacturing highlighted new utility and construction equipment, including tracked easement machines, service trucks, a material-handling unit and an all-electric aerial device. The Outback Series features digger derricks, cranes and bucket trucks on tracked carriers for off-road and tight-access work. The Voyager AMX combined a 7,500-pound crane with integrated air and power on an aluminum service truck, while a PalGal loader/cable rolloff offers heavy-duty material handling on a Peterbilt chassis. An all-electric bucket truck uses a high-voltage ePTO system for hydraulic power from the battery, providing zero-emission operation.

Alongside hosting the Hyundai Utility Expo Operator Challenge, HD Hyundai Construction Equipment North America debuted the HT38 compact track loader, a 115-horsepower machine with a 3,807-pound operating capacity and 10-foot-9-inch lift height. The loader included high-flow hydraulics, ride and creep control, a pressurized cab with heat and A/C and a heated air-ride seat. It supports a wide range of attachments and offers ground-level service access, a reversible fan and a tilt-up cooling module, backed by Hyundai’s three-year, 3,000-hour warranty.

Huber expanded its lineup with the Baron HX hydro excavator, the company’s first foray into the hydro excavation market, alongside new Lancer Series combination sewer trucks. The Baron HX features a 12-yard debris tank with twin tank vibrators for faster unloading, a telescoping boom with 330-degree rotation and six-foot extension and a tube-in-tube hose system to reduce maintenance. The Lancer Series included models with 9- to 12-yard forward-top loading debris tanks, high-capacity water systems, a 28-foot telescoping boom and a hydrostatic hose reel with 275-degree rotation.

LaValley Industries rolled out its PM1000 pole-setting attachment for articulating (knuckleboom) cranes, enabling operators to lift, grip, rotate and set poles entirely from the cab. The attachment offers 360-degree rotation, a secure grip and compatibility with a wide range of prime movers, reducing the need for tag lines and extra personnel. The PM1000 was demonstrated on an IMT articulating crane mounted on a Western Star chassis.

Teledyne Construction demonstrated a robotic utilities survey system that paired the Kobra 725 unmanned ground system with the UPAC Lite EM² sensor, allowing teleoperated mapping of buried ferrous and non-ferrous utilities, including pipes, cables and manhole covers, at depths more than 12 feet. The system can access hard-to-reach or hazardous areas and capture survey data compatible with Trimble Siteworks and Trimble Business Center.

Franna also displayed its AT24 US crane, highlighting features aimed at operator safety and load management. The model includes automatic counterweight detection, operator-settable working limits, front axle weight monitoring and real-time feedback on rated capacity. Safety systems include overload protection, Franna’s Dynamic Load Moment Indicator, an external emergency stop and an ergonomically designed operator cabin.

Safeguard introduced the Compass Core, a connected safety device that protects workers from electrical hazards in the field. Featuring a simple interface, it integrates with the Compass and Compass Pro systems and can be upgraded through software to expand functionality. Built for rugged use, the Compass Core works with other Compass Series tools to provide layered protection in high-risk environments.

CK Power Family of Companies highlighted utility-focused equipment for construction and maintenance work. Terramac featured its D14XL wheeled dumper for faster travel and heavy payloads, along with tracked carriers equipped with Terex digger derricks and vacuum excavators. CK Power displayed its CK7G-HC1 compact generator for hydraulic tools and the CKG250TVM5 mobile generator for field power, while Hayes Manufacturing showcased HEX Flex couplings and bearing-supported stub shafts to boost reliability and reduce downtime.

CM Labs Simulations expanded its utility training tools with new simulation solutions. Highlights included a bucket truck simulator developed with Altec, a horizontal directional drill training pack with full curriculum and hazard monitoring and a portable demo with Bailey International’s joysticks. The company also introduced a three-person crew simulation for excavator, articulated dump truck and dozer operators and added walkaround inspection training for boom lifts and horizontal directional drilling equipment to enhance pre-operational safety and readiness.

Record crowds packed the 2025 Utility Expo, where more than 22,600 attendees and 1,000 companies filled the show floor. After three days of steady traffic, hands-on demos and product unveilings across every corner of the Kentucky Exposition Center, the event reaffirmed its place as a key meeting ground for utility and construction professionals. The Utility Expo will return to Louisville Oct. 5–7, 2027.

Record crowds packed the 2025 Utility Expo, where more than 22,600 attendees and 1,000 companies filled the show floor. After three days of steady traffic, hands-on demos and product unveilings across every corner of the Kentucky Exposition Center, the event reaffirmed its place as a key meeting ground for utility and construction professionals. The Utility Expo will return to Louisville Oct. 5–7, 2027.